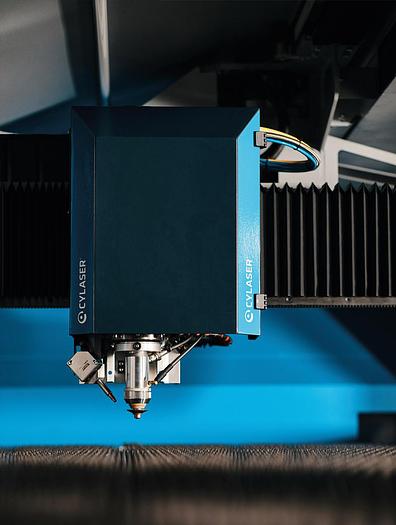

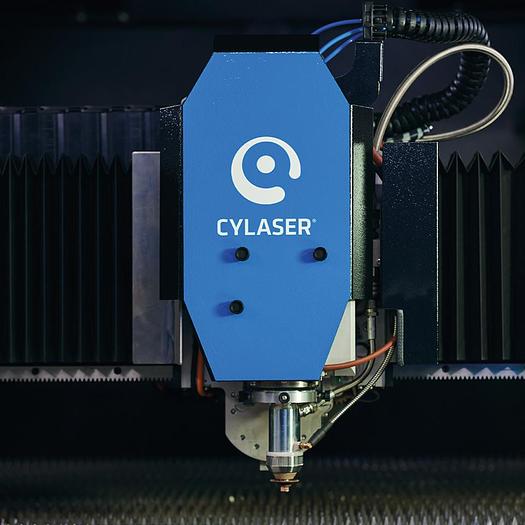

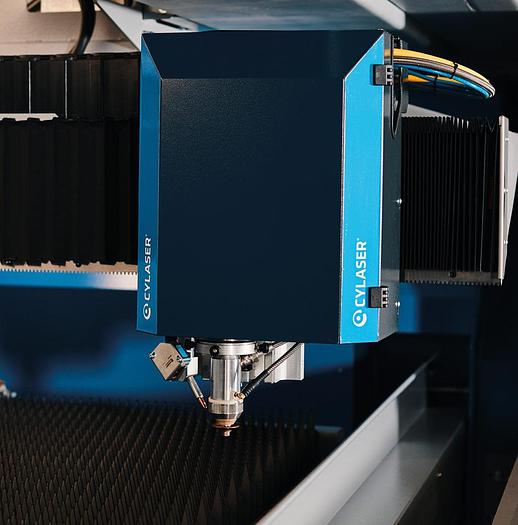

CUTTING HEADSEVO III AND EVO V HP

CUTTING HEADSEVO III AND EVO V HP

or

Call 049 7629563

Description

Optical configuration designed according to customer specifications

Maximum reliability guaranteed by the protective glass, even during maintenance

Magnetic anti-collision system to minimize machine downtime

Integrated process monitor to keep production under constant control

CYSP Servo piercing for fast and clean piercings on high thicknesses

Nozzle cleaning and automatic height control calibration

Predisposition for cutting with compressed air, as an alternative to the use of technical gases

Flycut function for high-speed grilling

Vortex function, for better quality and reduced gas consumption when cutting stainless steel

Management of marking and engravings and cutting of material protected by film

Management of the cutting process on powers equal to or greater than 8kW

Cy-laser, and in particular Livio Campana, founder of the company, is responsible for the discovery of fiber optic laser technology for

metal cutting. The year runs

, in fact, when the entrepreneur, already operating for decades in the sector of special machinery for the

welding,

fiber optic laser for 1070 ŋm wavelengths obtaining surprising results.

Thanks to this revolutionary discovery, Cy-laser becomes a pioneer in the creation of laser cutting systems and in a short time its name

echoes throughout the world. Having given life to this extraordinary technology undoubtedly represents enormous added value

for the company which, over the years, has never stopped but on the contrary has increased and refined its know-how by introducing a

cutting-edge product and always in step with the times. The cutting head, therefore, has gradually evolved and continues to do so today,

thanks also to the support of customers who represent the most important source of inspiration for Cy-laser.

There

it featured manual focus adjustment and was called

as it was equipped with a double focal length to make the most of the limited power of the generators of the time.

There

, instead, known as

, was designed in 2009 with a single focal length and automatic focus adjustment. And while in the double head the lens movements were all done manually, with EVO I all the moving parts were eliminated and the focal length therefore became a single, sealed block whose movements began to be controlled from the outside.

This represented a big step forward for the company and for the entire sector because making the

it was of great help to the production process and meant eliminating the occurrence of technical errors and the risk of incorporating dust or residues, but above all it ensured a longer life expectancy for the lenses.

With

a system was also introduced

to preserve the integrity of the head. Unlike the heads then and currently on the market, equipped with a breaking device, this system provided, in the event of a collision, the magnetic release of the torch and the immediate blocking of the machine to therefore avoid a possible breakage of the head. To this day we are still the only ones to offer this very useful solution and this represents one of the main added values that distinguishes us in the market.

Subsequently, thanks to the high know-how and continuous experimentation of the Cy-laser team, it was born

, then followed by

and from

, the current and most advanced cutting heads.

It was right with

, in 2018, that Cy-laser reached its pinnacle by designing and making a much more head

thanks to one

and at the same time solid and robust, capable of improving process dynamics and exploiting the increase in laser power of the generators.

This latest generation of heads is characterized by the introduction of some process options, including the automatic nozzle change, the automatic reflection control system, the particular head cooling system and the capacitive control system of the height of cut. Furthermore, Cy-laser has developed, over the years, two particular cutting processes: VORTEX and VEGA. While with the advent of EVO III two extraordinary innovations were born: the bevel cutting and the galvanometric marking head.

With

, the new head of the latest creation, Cy-laser aims to improve the cutting process with

(> 8kW), also for welding.

Contact us!

Make your fiber optic laser cutting system efficient and productive with Cy-laser automations.

Cy-laser SRL – Via Lago di Alleghe, 58-60 36015 Schio (VI) Italy T. +39 0445 576551 / P.I C.F IT03630330243 –

-

Specifications

| Manufacturer | CY-LASER |

| Condition | New |