CY-FAST MARK

CY-FAST MARK

Description

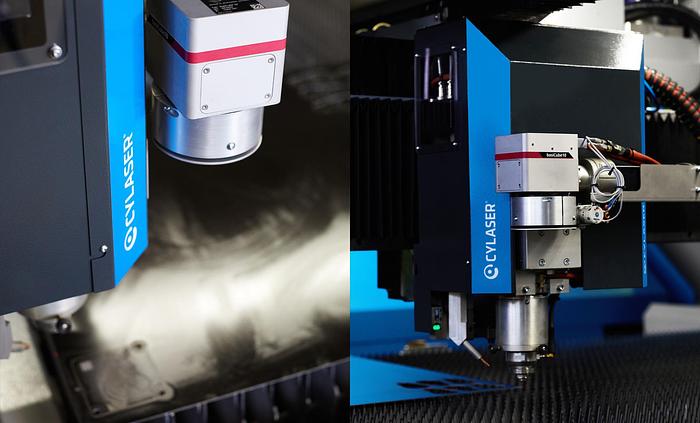

The installation of the galvanometric head, a standard accessory in the LM3015 system, allows for a which, compared to that of a traditional machine, allows you to necessary. Not only that, i and the possibility of to adapt to every need make it a very useful accessory that fits perfectly into the context . There in the company, in fact, it has become a fundamental operation for the contractor, who, by adopting this particular tool, manages to fully satisfy the customer by offering a compared to the competition. The marker acts on a limited working area which Specifically, it will then be possible to choose between Area 80x80mm (support in position 1 – Gantry LM Structure) Area 112x112mm (support in position 1 – Airplane Structure) Area 174x174mm (support in position 2 – Airplane Structure) Thanks to it will be possible Zonal marking. Specifically, all the markings included in an area, whose dimensions are given by the working area of the head, can be grouped and performed without further movements of the head The zone sequence Management of marking parameters Cy-laser has developed a to the galvanometric head of marking with the purpose d cutting, but during the execution of the post processor. The CAM generates parallel to the post cutting processor for the CNC a second post processor for execution of the markings. The “marking service” running on the CNC PC takes care of loading the paths into the marking card. The “drivers of communication” synchronize information between the marking service, the CNC and the marker controller board during the execution phase of the post processor. The marking service is a program without a user interface that has the task of orchestrating the , and which takes care of loading the marking part program in memory, to roto-translate it to the base to the orientation of the sheet metal, and to load it into the marker card. Low level communication operations are delegated to the drivers. I are the following: " The current (from which the name of the marking post processor) " L' " L' to be performed " The when loading the » What happened The marker acts on a limited working area which Specifically, it will then be possible to choose between Area 80x80mm (support in position 1 – Gantry LM Structure) Area 112x112mm (support in position 1 – Airplane Structure) Area 174x174mm (support in position 2 – Airplane Structure) Thanks to it will be possible Zonal marking. Specifically, all the markings included in an area, whose dimensions are given by the working area of the head, can be grouped and performed without further movements of the head The zone sequence Management of marking parameters Cy-laser has developed a to the galvanometric head of marking with the purpose d cutting, but during the execution of the post processor. The CAM generates parallel to the post cutting processor for the CNC a second post processor for execution of the markings. The “marking service” running on the CNC PC takes care of loading the paths into the marking card. The “drivers of communication” synchronize information between the marking service, the CNC and the marker controller board during the execution phase of the post processor. The marking service is a program without a user interface that has the task of orchestrating the , and which takes care of loading the marking part program in memory, to roto-translate it to the base to the orientation of the sheet metal, and to load it into the marker card. Low level communication operations are delegated to the drivers. I are the following: " The current (from which the name of the marking post processor) " L' " L' to be performed " The when loading the » What happened Contact us! Make your fiber optic laser cutting system efficient and productive with Cy-laser automations. Cy-laser SRL – Via Lago di Alleghe, 58-60 36015 Schio (VI) Italy T. +39 0445 576551 / P.I C.F IT03630330243 – -

Specifications

| Manufacturer | CY-LASER |

| Condition | New |