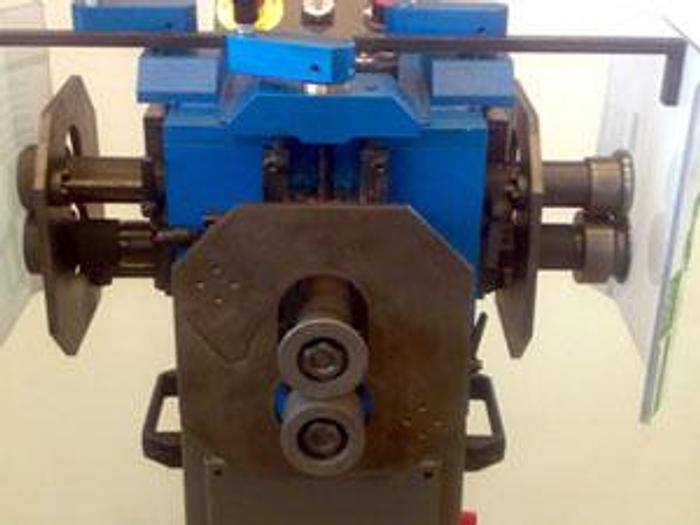

Three-headed edgebanders

Three-headed edgebanders

Description

The EDGE BANDERS carry out edging, ribbing and stapling work on iron, aluminium, copper and stainless steel sheets. They consist of an upper motor body and a lower base, fixed with four knobs. This determines an easy separation of the two blocks for transport with minimal space. In the TRIS versions the machine body can rotate on the base to facilitate operations that require changing the roller. The base is characterized by the presence of a large tool compartment closed with a lock. All models are driven by a gearmotor controlled by an electronic speed variator which allows, through a potentiometer, an easy and fast progression of the rotation speed of the rollers. It is also possible to make instantaneous reversals of the direction of rotation of the rollers as the electronic variator automatically controls the acceleration and deceleration of the motor. Furthermore, thethe use of ball bearings to replace bushings allows the roller rotation speed to be almost double that of traditional edgebanders. The Produtech edgebanders are equipped, for each processing head, with hardened steel reference plates which guide the sheet metal being processed without being scored or scored. Each processing head allows the adjustment of its backing plates. The upper roller of the Produtech edgebanders, operated by a manual lever with screw (manual version), or by a pneumatic cylinder (pneumatic version), moves vertically, lowering and raising on hardened guides, thus guaranteeing parallelism with the lower roller and avoiding the so-called movement scissor. SIZES AVAILABLE The edgebanders are offered in three sizes depending on the thicknesses to be processed; in particular, the 45 edgebanders can process sheet metal with thicknesses of up to 0.8 mm, the 55 edgebanders with thicknesses of up to 1 mm and the 65 edgebanders up to 1.5 mm. The determination of the maximum workable thicknesses is indicative, since the type of workmanship and the material are decisive. VERSIONS The edgebanders are made in two versions; MONO, i.e. with a single working head (pair of rollers) and TRIS, with three working heads. The TRIS models, equipped with three pairs of rollers with different shapes, allow complex processes that require multiple steps in sequence such as the stapling of valve boxes, the stapling of sheet metal, the tapering and joining of pipes and bends, etc. The use of TRIS edgebanders therefore allows for a reduction in working times (roller changes are avoided), a reduction in overall dimensions in the workshop or on the construction site (a single machine is used instead of three. PRODUTECH PNEUMATIC EDGE BANDERS The pneumatically operated PRODUTECH edgebanders, in the MONO 45, 55 and 65 versions and in the TRIS 45, 55 and 65 versions, have the upper edgebanding roller operated not by the screw with manual lever, but by a pneumatic cylinder controlled by the same pedal that controls the rotation of the rollers. The pneumatic cylinder is equipped with an adjustable mechanical stop which allows you to determine the working depth. Furthermore, using a pressure regulator and a timer inserted in the control panel of the edge banding machine, it is possible to set an automatic work cycle which allows the edge banding rollers to gradually penetrate the sheet metal simply by pressing the pedal. This means that the operator no longer has to put effort on the manual screw of the upper roller, but above all he has both hands free to support the sheet metal or the piece being processed.

Specifications

| Condition | New |

| Stock Number | 39 |